About us

Pa-Wang Ceramic Industry Ltd., a Trendy and Luxury Tiles Manufacturing Project located at Banani, Bogura, Bangladesh. A group of globally renowned professionals and experts in various fields of technology, research, design and quality are fully dedicated for R & D to present only Premium and Stylish quality tiles in Bangladesh to satisfy the present and future needs of the customers. Due to our teams ‘creativity and innovation’ our design stands unique. Pa-Wang has set its sight on all these factors adopting new production techniques in order to enhance the quality of its products.

Pa-Wang's manufacturing units are equipped with State of the Art Environmentally friendly modern technology. Full automation ensures a zero chance for human error, this allows Pa-Wang to deliver European Brand ‘ROMA’ products at the highest standard to the customers. ROMA has been established in Bangladesh by the professionals from all over the world with multiple decades of industry experience, proven ability, innovations & patronage.

The rapid growing demand for style and aesthetics is the inspiration behind every design of ROMA Brand and its pace to keep up with the customer and market demands has made ROMA a synonym for quality, service and innovation.

ROMA Products are suitable for indoor Floors of Home, Commercial Complexes, School, Colleges, Universities, Hospitals, Prayer halls, Community halls/Centers, Airports, Rail Stations, Restaurants, Coffee Shops, Bars etc. Those who feel that floors should be an extension of the beauty reflected for them, ROMA represents an inspired creativity and unparalleled commitment towards quality. Pa-Wang already adopted technologies & standards with the changing times & willing to implement prior of its need.

Board Of Directors

SM Mahbub Alam

Managing Director

Ishrat Hossain

Director

Abdul Hamid

Director

Abdul bari

Director

Md. Ashrafuzzaman

Director

Iftekhar Hossain

Director

Sultana Hossain

Director

Jasmin Sultana

Director

Award and Achievments

Membership Certificate of BCMEA

Bangladesh Ceramic Manufacturers & Exporters Association

Membership Certificate of Ceramic ISC

Ceramic Industry Skills Council

Certificate of Registration (ISO)

QFS MANAGEMENT SYSTEMS LLP.

This is to Certify that the Quality Management System of PA-WANG CERAMIC INDUSTRY LTD., Has been found to be of the Quality Management System Standard - ISO 9001: 2015

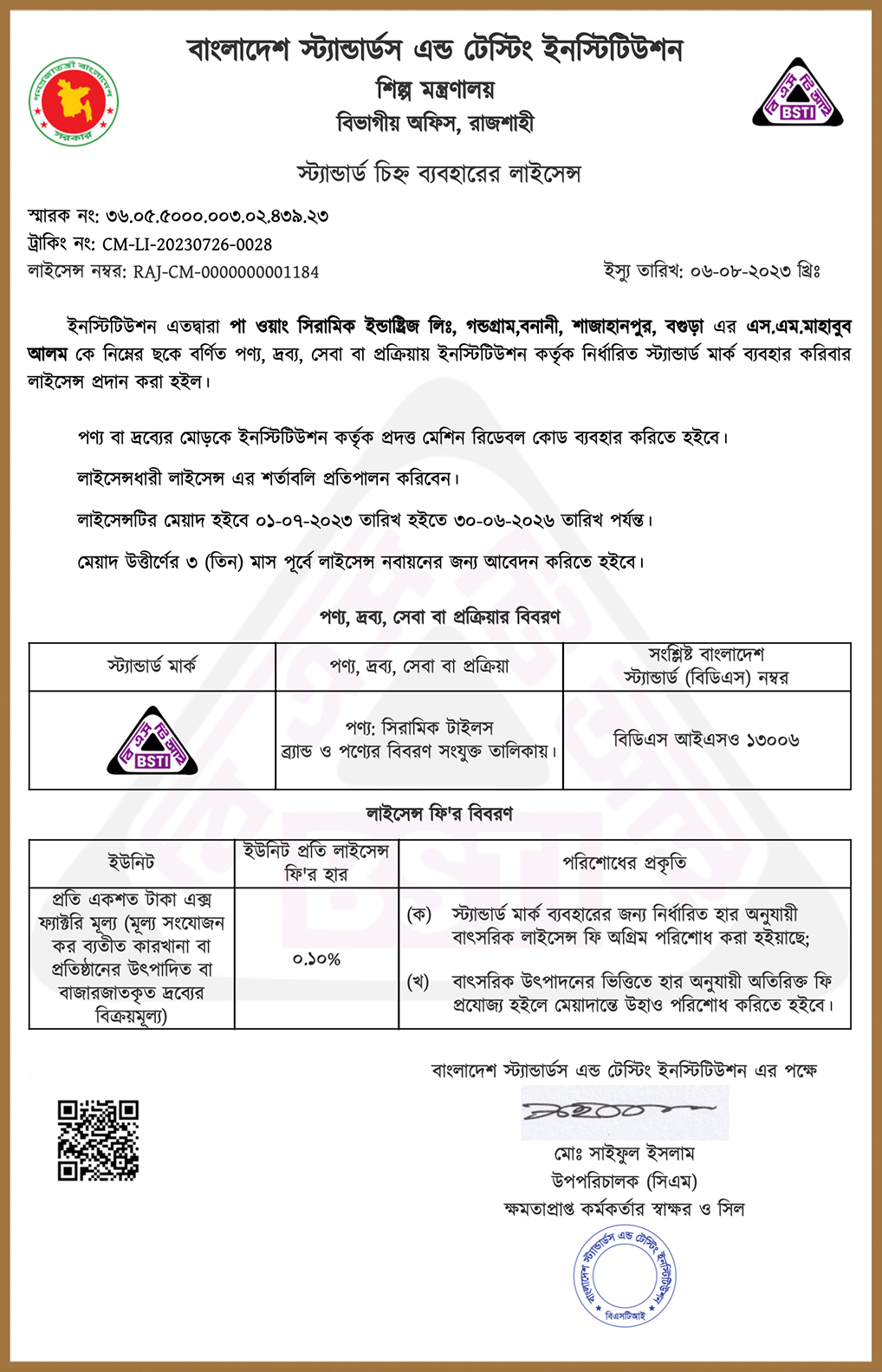

Certificate of BSTI

Bangladesh Standard & testing Institute

REHAB Fair Award - 2022

Real Estate & Housing Association of Bangladesh (REHAB) Fair 2022 which was held at Bangabandhu International Conference Center (BICC) near Agargaon, Dhaka, DECEMBER 2022,

REHAB Fair Award - 2021

Real Estate & Housing Association of Bangladesh (REHAB) Fair 2021 which was held at Bangabandhu International Conference Center (BICC) near Agargaon, Dhaka

OUR MISSION

To thrill our customers with great design and value proposition driven by continuous improvements in tile creativity, innovation, efficiency and customer service.

OUR VISION

- We are committed to designing and manufacturing the best ceramic tiles from our leading Bangladesh factory, to be the market and brand leader.

- To continue to provide unrivaled service and exceptional value for money to our growing customer base.

- To provide a sustainable future for our talented employees.

OUR VALUES

Pa-Wang Ceramic Industry Ltd., passionately believes in the people who have built this successful business. We should all be proud of the exceptional business we have created and remember the core values this has been built upon:

- Innovative

We exceed expectations through our creativity, from design and manufacturing to delivering intelligent customer solutions through products and commercial innovation. - Brave

Let’s continue to be brave. To drive improvement and innovation, to keep challenging and allowing ourselves to be challenged. We’re not the ‘norm’ and never will be. We believe in providing modern solutions for our customers to ensure the sustainable future of our business and shared community. - Collaborative

We have worked hard to create our brand and have built our future collaboratively together, moving forward without fear of a changing world. This takes honesty, loyalty and respect, values we are proud to be associated with. - Proud

We’re proud to be a Bangladeshi manufacturer, supporting traditional craftsmanship and responsibly producing quality ceramic and porcelain tiles to Bangladesh and to also export globally.